How is rubber made?

The most widely used mat material’s origin story.

Rubber is one of the most versatile materials on the market. Matshop alone uses numerous different types, each with a slightly different job suited to its properties. While anti fatigue rubber foam matting needs spongy support, kitchen mats need to be grease- and water-resistant.

Despite its widespread use – in the matting industry and beyond – many of our customers are surprised to learn how rubber is made. It isn’t something that people tend to think about, but it is an interesting topic. So, we are answering this question: how is rubber made?

The benefits of rubber

One of the reasons that rubber is so popular is its durability. Rubber is extremely tough and can withstand even the highest traffic levels. This durability holds even when subjected to liquids, wheeled traffic and a constant flow of boots, so rubber matting is ideal for industrial use.

Despite its strength, rubber is also very flexible. It’s the most common material used in anti fatigue matting because it provides that sturdy support while also allowing your muscles to make the micro-movements they need to avoid cramps, fatigue and injury.

Finally – but perhaps the most important safety feature of rubber – it has natural slip-resistant properties. That means any rubber mat used for any application will double up as a non slip mat. If you care about keeping your employees, customers and loved ones safe, that will be a big deal.

A hidden benefit: it can be great for the world

Another thing about rubber that many people don’t know is that it can be created quite sustainably. You should bear in mind that this is not always the case, and there are numerous unethical rubber sources. But, rubber can be created in an eco-friendly way.

Firstly, rubber is technically biodegradable. We take this with a pinch of salt because it takes an extremely long time to break down (think 50-100 years!). Even if it takes a lifetime, that is still better than plastic.

As with anything, reusing trumps recycling, so the main way that rubber is good for the planet is in its potential to be reused and upcycled. There is now a huge range of businesses recycling rubber from various items headed for landfill. These items are then broken down into rubber pellets and made into new items…like anti fatigue rubber mats.

So, how is it made?

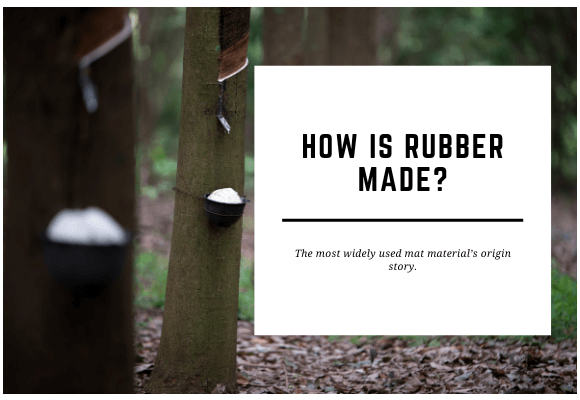

Natural rubber is contained in a milky liquid that can be found in the centre of trees. This liquid is called latex, and is usually extracted from the Hevea brasiliensis tree. The latex is contained in vein-like networks within the trunk, so extracting it does not have to damage the tree.

Each tree can be ‘tapped’ every 2 days for almost 30 years. When you compare that to the trees grown to become coffee, palm oil, wood or paper, that seems like a much better method. Environmentally conscious matting is always the best option in our opinion.

The latex is extracted by making a specific incision into the tree’s bark, slightly exposing one of the latex-containing tubes. Gravity is then left to do its work, which can last 5 hours! After that, the tree will start to repair itself and the whole process can happen again 2 days later.

This process must be expertly done, because too much of a cut will cause the latex to harden. That is thought to be the natural function of latex – to aid plants when repairing themselves. Something like human skin scabs over, latex dries and hardens to cover a wound. What about synthetic rubber?

What about synthetic rubber?

You might have heard that rubber comes in two forms: natural and synthetic. We have spoken so far about the natural type, but it’s the synthetic one that doesn’t grow on trees! Synthetic rubber isn’t as environmentally-friendly, because of the way it’s made.

Synthetic rubber is made from fake latex, which is made from the by-products created mostly by the crude oil industry. While this might sound like a good use of waste, the use of fossil fuels for production has an overall negative impact on the environment.

Anything made from crude oil is a plastic, so synthetic latex won’t biodegrade and is more likely to end up in the ocean. As well as being bad for the planet, it’s more likely to contain harmful toxic off-gasses. For more information on these, check out how to get rid of the rubber smell.

Which type of rubber is best?

In terms of human and planetary health, natural rubber wins every time. It is much more sustainable and less toxic than synthetic rubber. But, we need to remember that both types of rubber are toxic when burnt.

Toxicity aside, there’s another reason people might choose synthetic rubber over its natural counterpart: strength. Synthetic rubber has a higher melting point and is generally more durable than natural rubber. So, for some jobs, natural rubber just won’t cut it.

For matting, we almost always go for natural rubber. Unless you are planning to install your mat in a 180° climate, or need your product to withstand extreme movement, the benefits of going au naturale outweigh the durability of synthetic rubber.

How different types of rubber are made

When we talk about rubber, it’s easy to forget that one size doesn’t fit all. Rubber comes in many different forms, and some manufacturing processes are sustainable while others aren’t. Rubber in general is an eco-friendlier option than, say, plastics, but improvements can always be made.

At Matshop, we always strive to source the best possible materials. It’s how we can confidently say that we make the best possible products! Usually, that means using natural rubber. But it always means knowing exactly where the rubber in our rubber mats comes from.

For more information on our supply chain, production methods and sustainability statement, or to get a more personalised recommendation for your matting applications, reach out to the team at any time. We are always happy to hear from you using the chat function below or call 1300 628 746.